Modular construction method uses modules (blocks, panels) pre-manufactured at the factory for assembly at the construction site. Modules are manufactured on modern automated lines, ensuring high precision and uniformity. As a result, modular construction works have high quality, minimizing errors and material waste.

Benefits of the modular construction method

The construction industry is growing, requiring advanced, efficient and economical construction solutions. In that context, the modular construction method (also known as prefabricated construction) is emerging as an inevitable trend, bringing many outstanding benefits compared to traditional construction methods.

1. Fast construction speed:

This is one of the most outstanding benefits of the modular construction method. The modules are pre-manufactured at the factory according to modern processes, ensuring high precision and uniformity. Thanks to that, construction at the construction site takes place quickly, saving 30-50% of time compared to traditional construction methods.

2. High quality construction:

The module manufacturing process is strictly controlled by an automated machinery system, ensuring high and consistent quality. Module construction at the construction site is also carried out by a team of skilled workers, ensuring accuracy and safety. Thanks to that, the construction using modules has high quality, minimizing errors and material waste.

3. Labor safety:

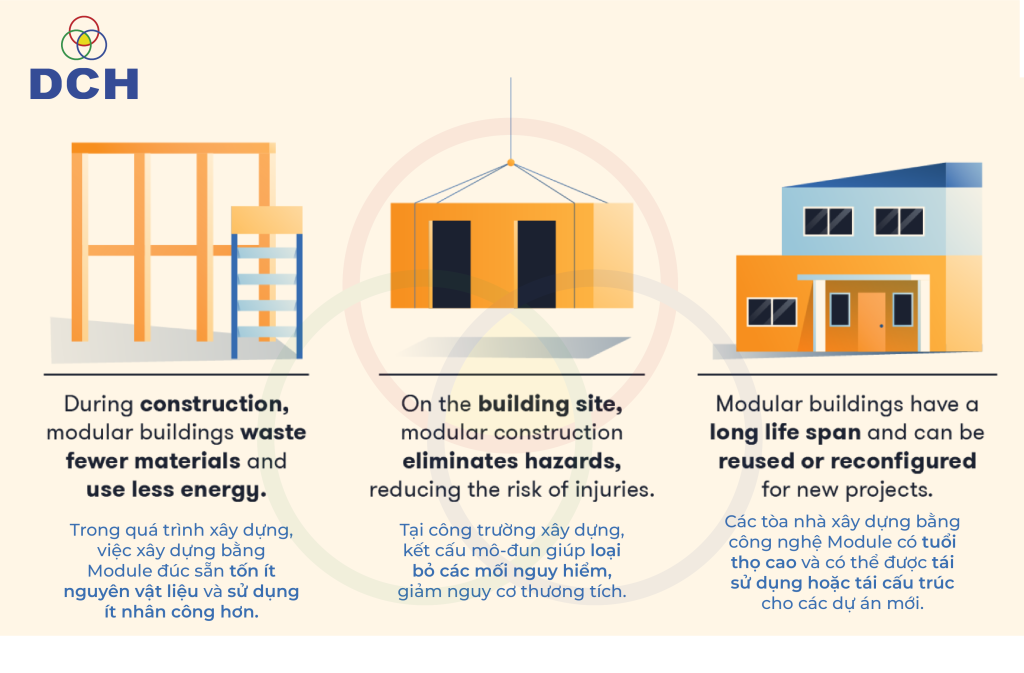

Manufacturing modules at the factory helps reduce the risk of occupational accidents compared to construction at the construction site. Modules are manufactured in a safe environment, minimizing dangerous factors such as dust, noise and chemicals. In addition, module construction at the construction site is also carried out according to strict labor safety procedures, ensuring safety for workers.

4. Minimize environmental impact:

The modular construction method helps to minimize environmental impact compared to traditional construction methods. The module production process is strictly controlled, minimizing construction waste. The module construction at the construction site is also quick and neat, minimizing noise and dust.

5. Cost savings:

By shortening construction time and minimizing material and labor waste, modular construction can help save costs for investors. The cost of modular construction is usually 10-15% lower than traditional construction methods.

6. High flexibility:

Modules can be easily disassembled, moved and reused, bringing high flexibility to the project. Thanks to that, investors can easily change the design or function of the project in the future.

7. Suitable for many projects:

The modular construction method can be applied to many different types of projects such as houses, apartments, hotels, hospitals, schools, factories, etc. Thanks to its outstanding advantages, the modular construction method is increasingly popular and widely applied in the construction industry.

DCH DATA CENTER IS BUILT BY MODULAR METHOD

DCH data center is built according to the solution prefabricated module for Data Center Infrastructure. Instead of building a traditional Data Center from scratch, prefabricated Data Centers are built in a controlled factory environment, then shipped to the Data Center site for assembly and integration.

This approach utilizes modular components that are designed, manufactured, tested, and assembled completely off-site. Prefabricated Data Center modules have many advantages that make them an ideal choice for large-scale projects, such as Vietnam’s largest Level 4 Hyperscale Data Center.

In addition to the above advantages, when using this method to build a Data Center, other advantages that cannot be ignored are:

Resilience and redundancy:

Fault-tolerant design: Prefabricated modules can be designed to meet the highest standards of resiliency and redundancy, such as TIA-942 Level 4 certification. This design ensures that the Data Center can continue to operate smoothly even in the event of component failure or power outage.

Disaster Recovery: Modular architecture allows for rapid deployment of additional capacity to meet unexpected needs or disasters. This flexibility enhances the Data Center's disaster recovery capabilities and ensures business continuity.

Within the Digital HUB Data Center project, each Data Center hall consists of 1,200 racks with a total IT capacity of 15MW, divided into 30 IT modules. Each module, with an IT capacity of 500kW and 40 racks, can be prefabricated on site. This approach not only speeds up deployment, but also ensures that each module is built to exact specifications, performance tested and ready for integration out of the box. The modular design facilitates easy scalability, allowing the Data Center to expand incrementally without major disruption.

Meeting the Growing Demand for AI Data Centers:

The demand for AI Data Centers is growing rapidly, driven by the exponential growth of AI and machine learning applications. In Vietnam, this trend is particularly evident due to several factors:

Digital transformation: Vietnam is undergoing significant digital transformation across various sectors, including finance, healthcare, and manufacturing. AI technology is at the forefront of this transformation, requiring robust and scalable Data Center infrastructure.

Government Initiative: The Vietnamese government is actively promoting the development of AI and digital technology. Initiatives such as the National AI Strategy to 2050 aim to make Vietnam a leading AI hub in Southeast Asia. This has spurred investment in AI research, development and infrastructure, increasing the demand for dedicated data centers.

Technology industry growth: Vietnam’s technology industry is growing so fast, with many startups and established companies focusing on AI solutions. This growth is driving demand for Data Centers that can support high-performance computing and large-scale data processing.

Enhanced data generation: The proliferation of IoT devices, social media, and e-commerce platforms in Vietnam is generating massive amounts of data. AI applications require significant computing power to analyze and derive insights from this data, further driving the need for advanced Data Centers.

Choosing the prefabricated modular construction method for the Data Center project provides strategic advantages by accelerating deployment, reducing costs, ensuring high quality and reliability, while enhancing scalability and sustainability.

These benefits make prefabricated modules the ideal solution to meet the ambitious goals of Vietnam’s largest Level 4 hyperscale data center, supporting its growth and operational excellence in a rapidly evolving digital landscape. In addition, the ability to rapidly scale and support AI applications enables the data center to meet the growing demand for advanced computing infrastructure in Vietnam, in line with the country’s strategic goals for AI and digital transformation.